04.06.2020

Heat storage in PCM materials

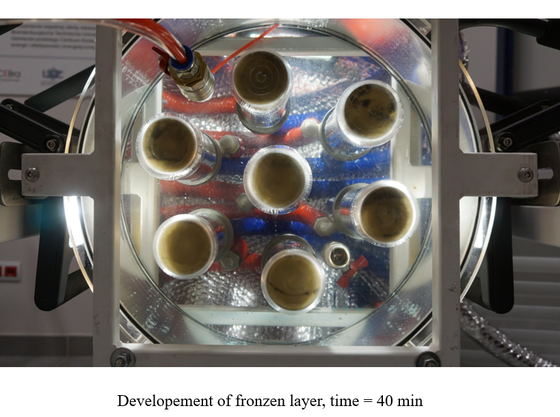

Heat storage in PCM materials (Phase Change Material), based on the use of phase transformations: solidification and melting is quite well known in literature in the field of energy. Examples of analysis of such phenomena are presented in enclosed material and discussed in the literature cited therein. Devices in which heat is stored and released are called heat accumulators. The aim of a heat accumulator is to store energy in the heat mode during the period of its surplus, and then release it during the period of its shortage. The PCM material that stores and releases energy is selected according to its type and external geometry. The PCM material used in heat accumulators has the ability to store a relatively large amount of heat per unit mass of material compared to other methods of heat accumulation. Thanks to the use of heat accumulators, the rational energy management allows to reduce its consumption, and thus ultimately leads to fuel savings. The second significant benefit, resulting directly from lower fuel consumption, is a reduction in the emission of harmful combustion products to the natural environment. Choosing the optimal construction and size of a heat accumulator is one of the main tasks for heat accumulator designers. The very important parameter for a heat accumulator is the ratio of the volume to the external surface area. Through that surface the heat is supplied or extracted to the heat transfer mediator. This presentation discusses the different shapes of PCM materials due to the effective heat transfer conditions. Water was used as the representative PCM material for the solidification test. It’s also a useful test material due to the possibility of its multiply use without destroying the test stand. Water also allows to observe all important elements of the solidification process. More information can be found on the learning platform.